Wireless Data

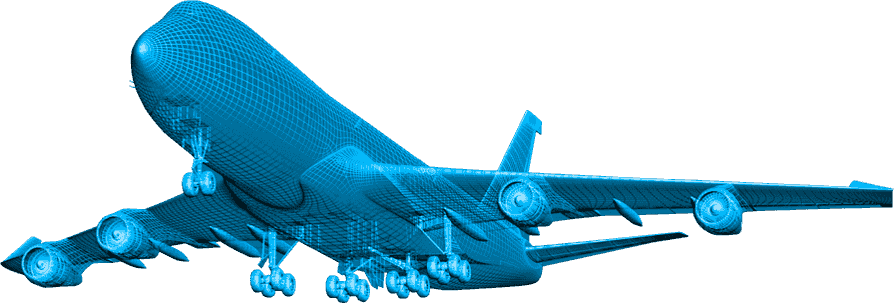

The new age of flight operations efficiency

By Woodrow Bellamy III

Presented by:

Increasing the efficiency of flight operations in today's ultra-competitive global aviation industry requires operators to take advantage of 21st century data automation solutions. Airline operational teams need to get their aircraft in and out of airports as quickly as possible, aiming to maintain flight schedules while also constantly monitoring the conditions of their aircraft to ensure safety. And it helps that operators no longer have to wait for an aircraft to land to evaluate its condition and maintenance needs.

In today's environment, data acquisition is more important than ever, according to William Cecil, director of business development at Teledyne Controls. As passenger jets continue to become smarter with increasingly data centric architectures, the tools that operators use to monitor the flying conditions of their fleet will not only become increasingly rigorous, but also getting the right data to these tools at the right time will become increasingly important. "Basically, the data acquisition unit, whether it’s on a Boeing or an Airbus or any aircraft, really fits in the middle of the information world, because it’s actually connected to dozens and dozens of databuses and it listens to just about everything on the aircraft, and it also feeds the data that has to get to the flight data recorder," said Cecil. "Typically the regulations increase that requirement more and more; so that more and more data gets sent and for every generation of aircraft it gets bumped up a level."